The Brewing Process

Quality, consistency and innovation are key to creating amazing and beautifully balanced beer.

To hear from the team on how our beer is made, book yourself onto the Thornbridge Experience

The Brewing Process

Each Process in detail

-

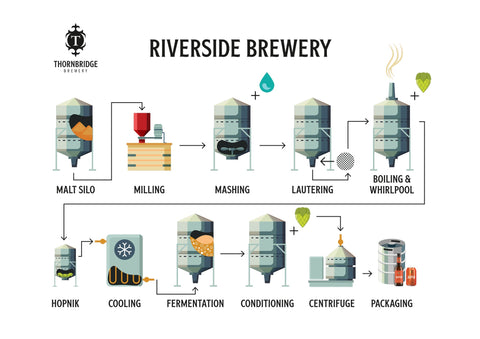

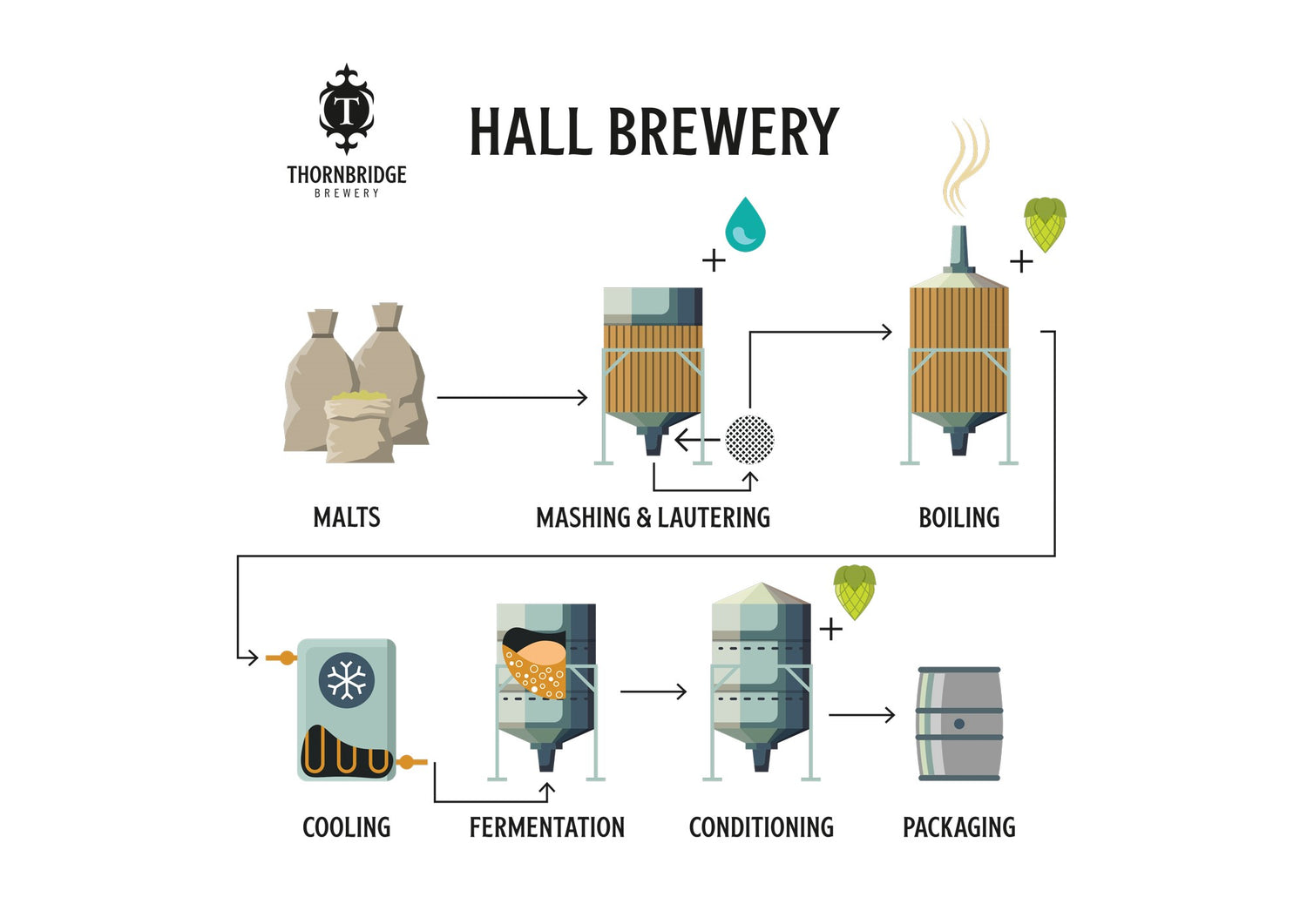

Malting is the process of steeping, germinating and drying grain to convert it into malt

-

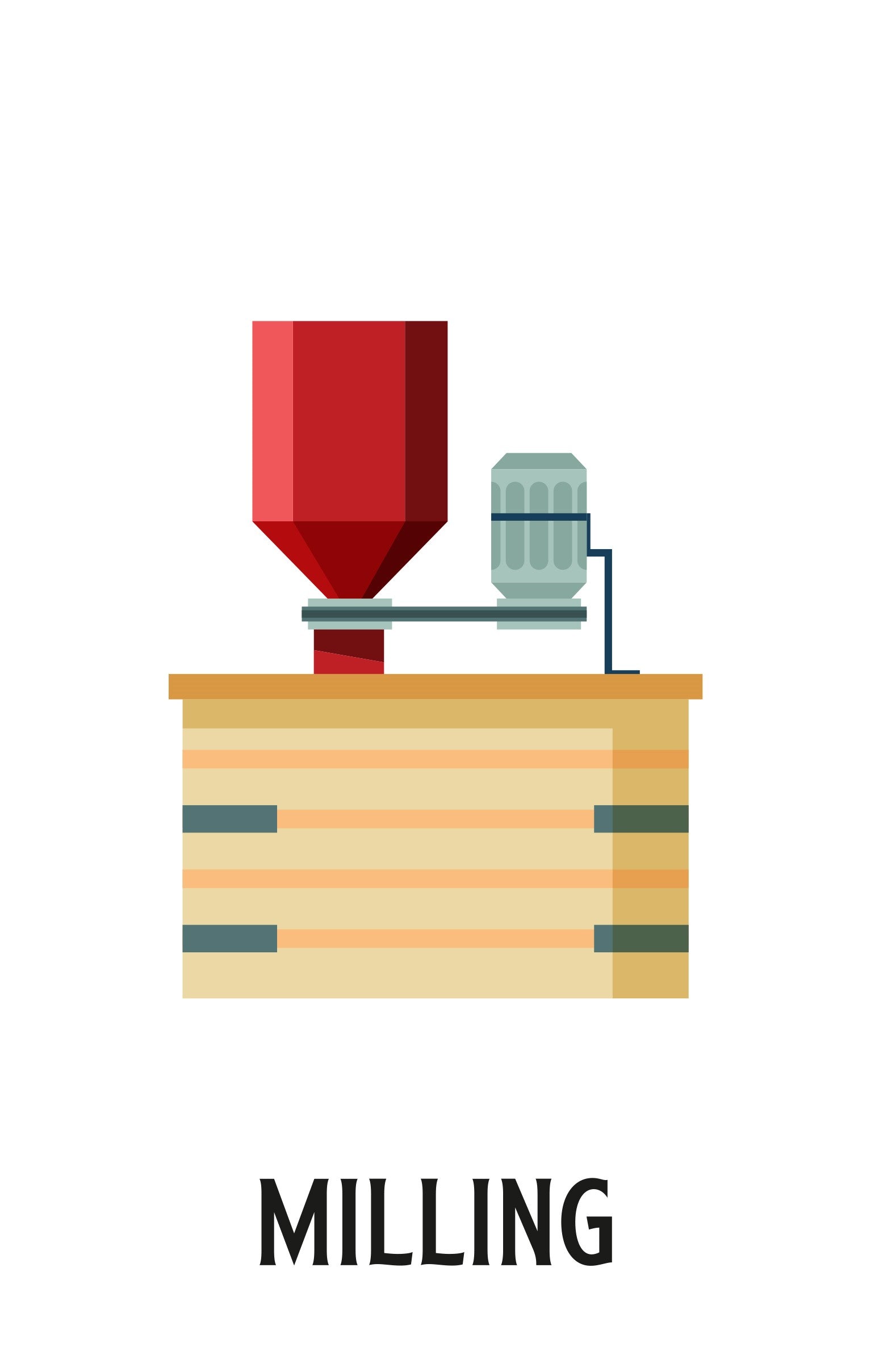

Milling is the physical crushing of malt kernels into smaller particles in preparation for mashing and lautering. The various milling processes need to be manipulated carefully to find a balance between a grind that is too fine and one that is too coarse.

-

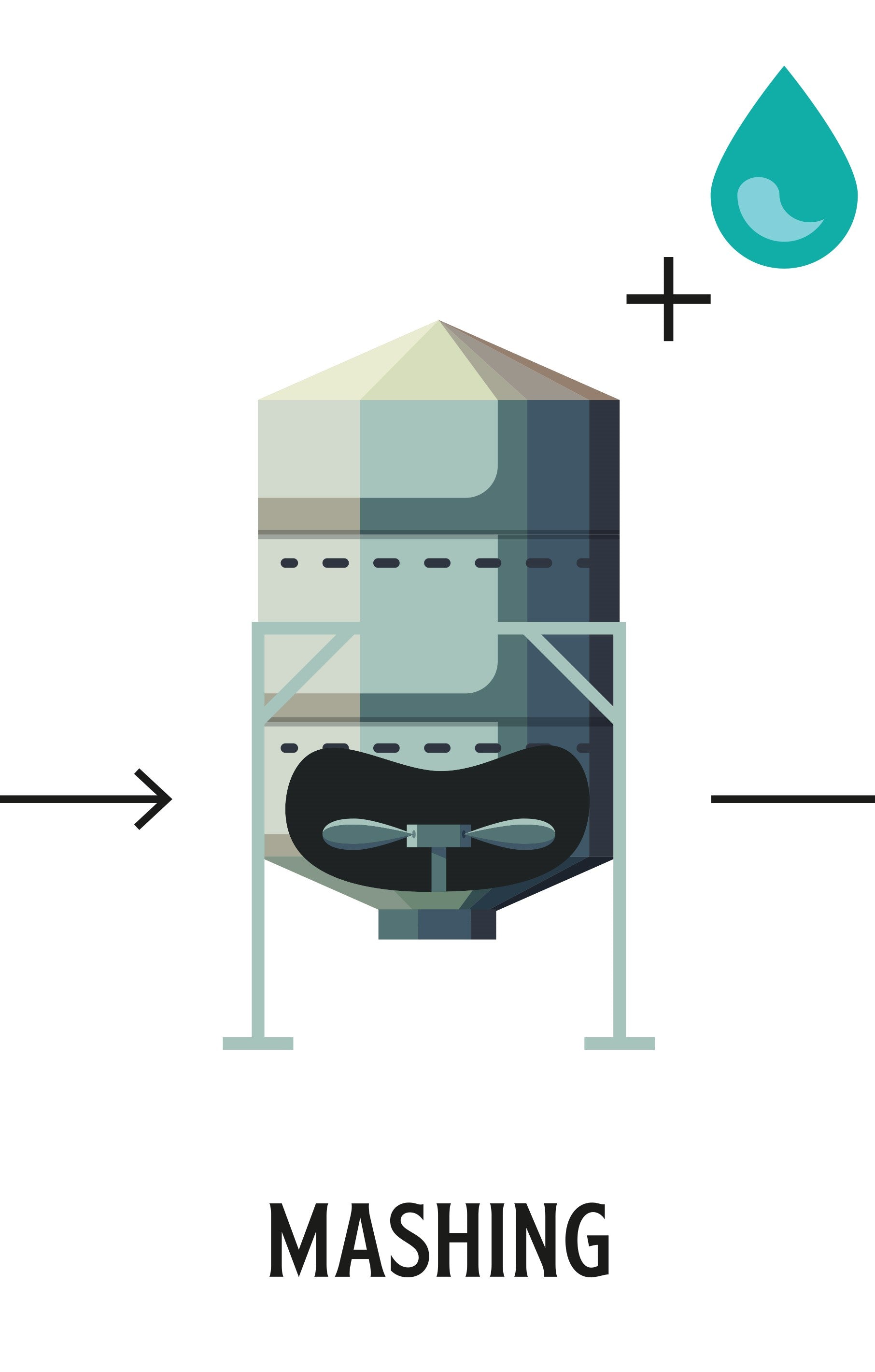

Mashing is the term given to the start of the brewing process, where crushed grains are mixed with water to form a porridge-like mixture called the “mash.” It is in the mash that malt and other cereal starches are transformed into sugars and proteins and other materials are made soluble, creating the sweet fermentable liquid called the wort.

-

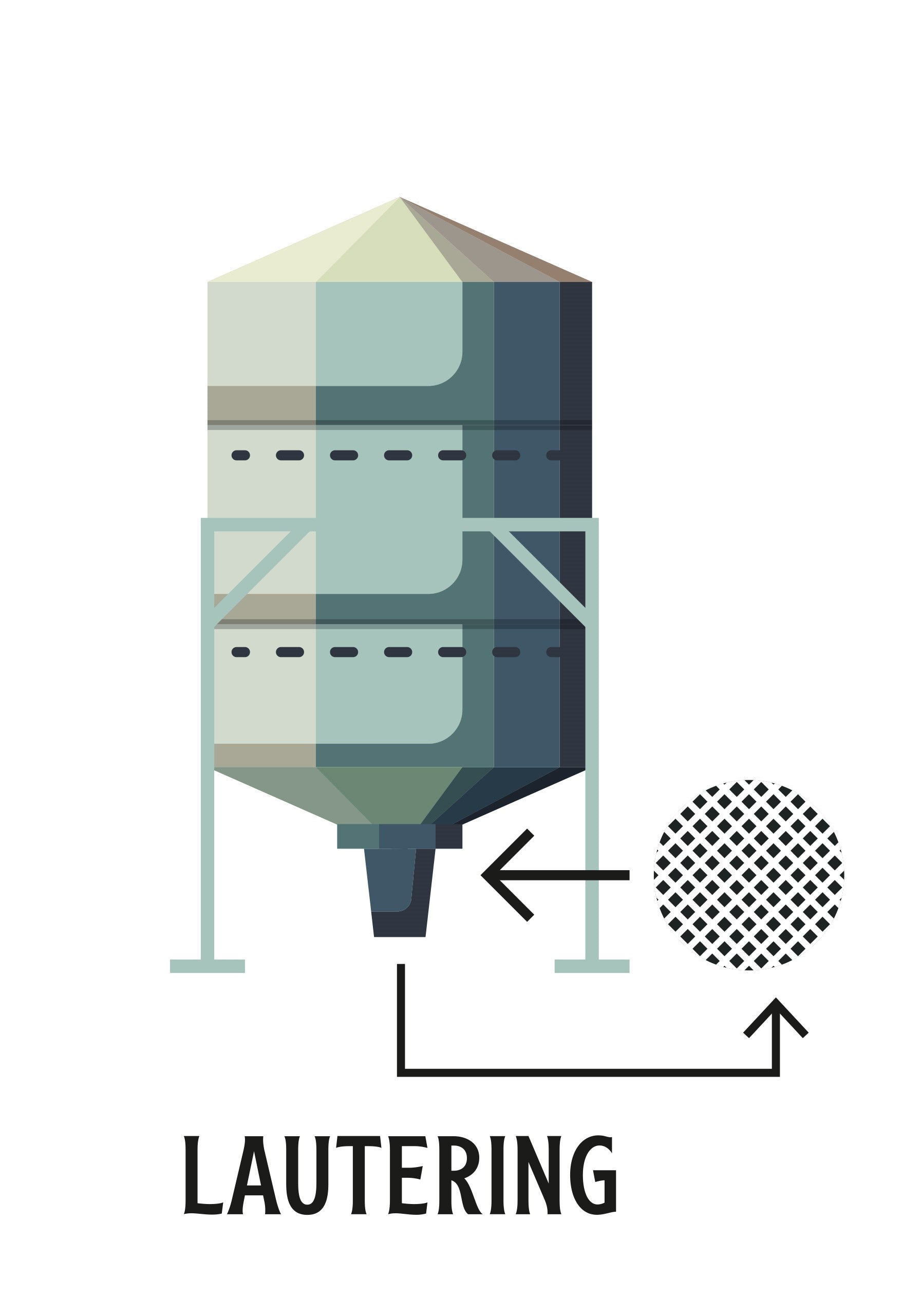

Lautering is a method of separating sweet wort from spent grain. Historically, mashing and lautering often took place in a single vessel but brewers soon realized that optimizing separate vessels for each part of the process of wort generation and recovery would lead to improved beer quality.

-

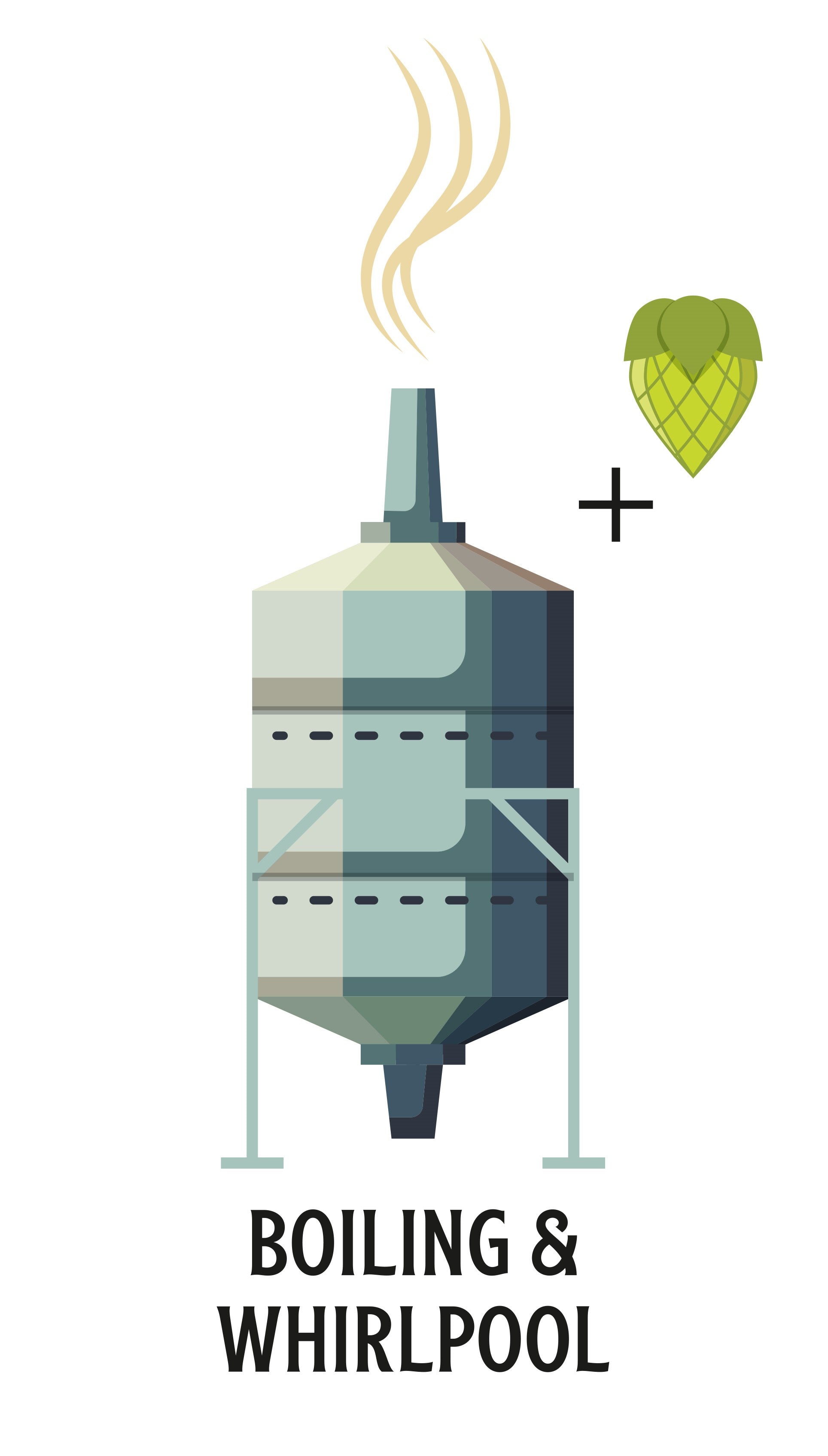

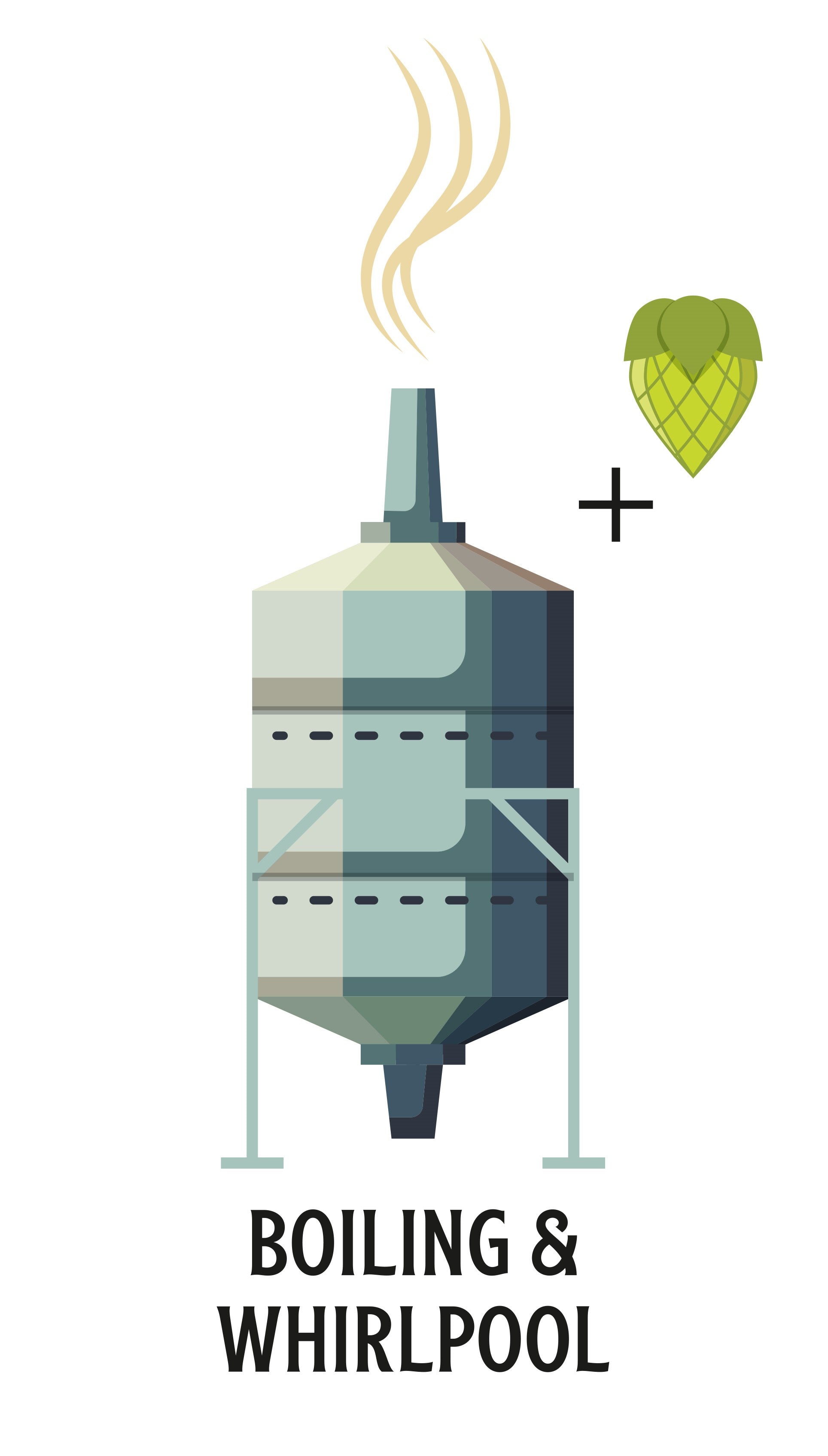

Boiling wort is one of the most crucial and complex aspects of the brewing process and Whirlpool is the method of separating hop fragments and other solid particles from hot wort.

-

In the hopnik the boiling wort pass through a bed of whole leaf hops without losing any of the fabulous aromas

-

fermentation vessels are fitted with hollow jackets that chill parts of the interior surface of the vessel on demand. This allows brewers to set a maximum temperature during active fermentation and then easily chill the beer for further processing

-

Fermentation is the process by which yeast converts the glucose in the wort to alcohol and carbon dioxide - giving the beer both its alcohol content and its carbonation. To begin the fermentation process, the cooled wort is transferred into a fermentation vessel to which the yeast has already been added. The fermentation time and temperature varies on the style of beer

-

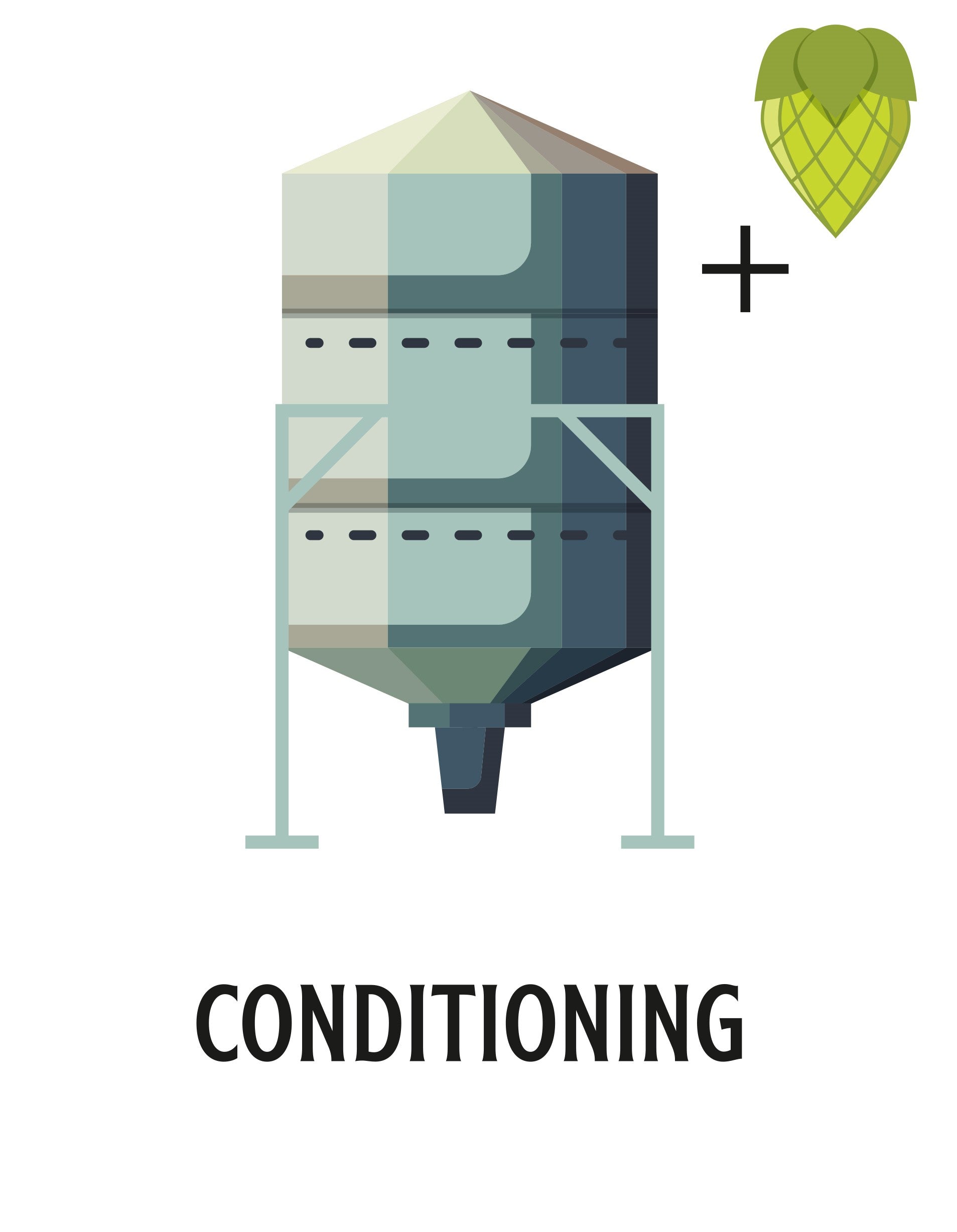

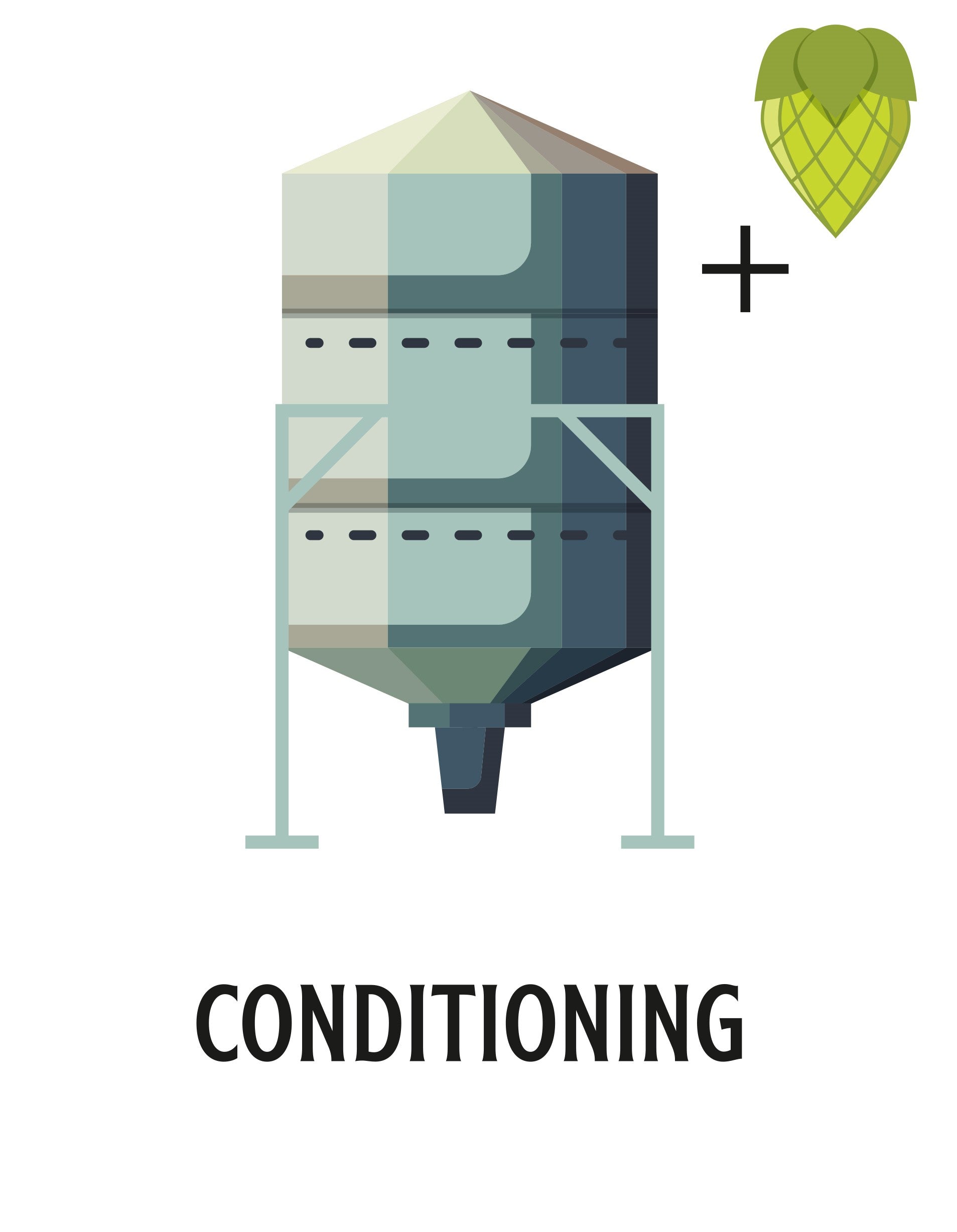

Conditioning is the achievement, post-fermentation, of a particular beer’s correct character of maturation and carbonation,

-

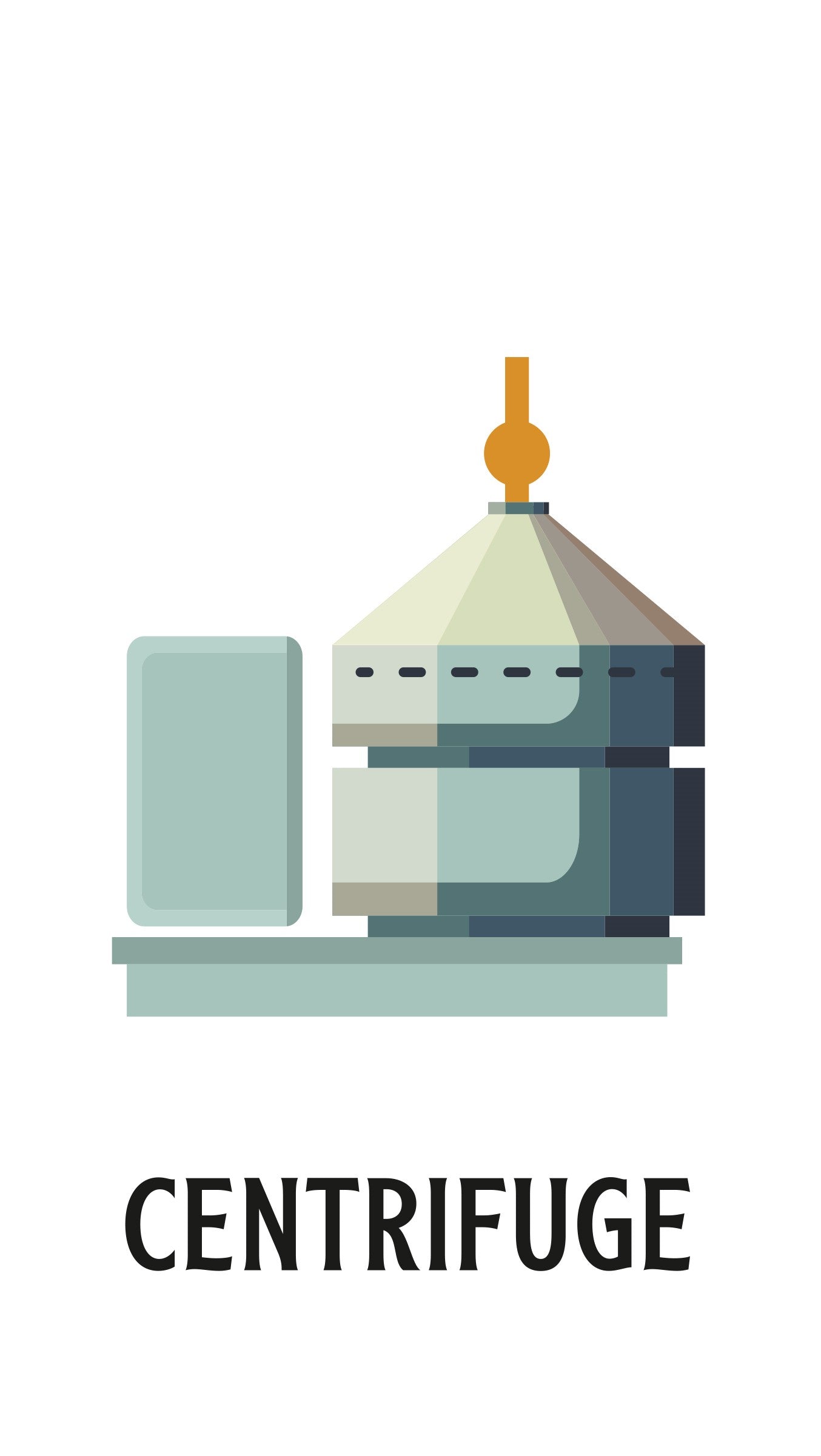

Seperating the finished beer from the other particles including yeast, trub, and hop residue

-

Depending on what has been brewed after all stages, beers are packaged into either Cask, Kegs, Cans or Bottles

The Hall Brewery

The original hall bewery kit is now behind the taproom and is used to brew smaller runs and our speciality cask beer range